“Great communication with everyone from the top down. It’s a pleasure working with Nuway and their crew. If issues do arise, it’s the positive attitude of the employees and their willingness to help that allows for problems to be solved easily, simply, and in a timely manner.”

what is ppe?

Work in the construction industry has always posed a higher risk for physical injury than work in other industries. Even today, the US construction industry reports over 150,000 work-related injuries per year, an alarming percentage of which end in fatalities. Naturally, these higher rates of potential risk have led to continual innovations in safety measures, starting with advances in PPE.

Personal Protective Equipment (PPE) is an umbrella term for the specialized gear worn by individuals to protect them from potential hazards. This includes things like hard hats, safety goggles, high-visibility clothing, hearing protection, fall protection, gloves, respiratory protection, and more.

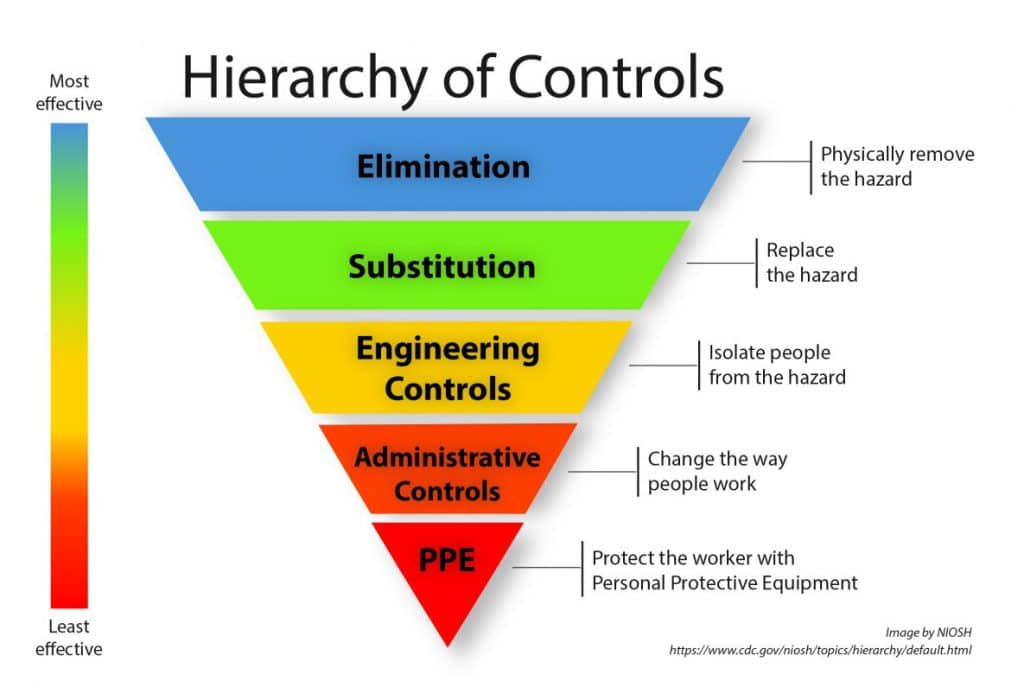

In the construction industry, PPE is the last line of defense against job site hazards like falling debris, faulty equipment, and chemical exposure. According to the hierarchy of controls, there are five levels of reducing or removing hazards to avoid the risk of injury or illness. They are arranged in order of effectiveness, with PPE at the bottom of the list.

PPE in the past

With the changing work landscape brought on by the Industrial Revolution, new hazards were introduced to the common worker. The rise of factories, mills, and other manufacturing facilities meant a rise in heavy and complex machinery as well as exposure to chemicals, creating a need for better safety measures. But, alongside the growing risk of hazards came a growing opportunity for advancement. New materials and more efficient machines made it easier to produce and improve PPE items like the hard hat.

the Evolution of the hard hat

The concept of protective helmets is not a new one. Many cultures have crafted head protection out of metal, leather, and other materials for thousands of years. But the first iteration of the modern hard hat was born just over a century ago in 1919, when E.W. Bullard, an industrial equipment supplier, developed the “Hard Boiled Hat” – made of canvas, glue, and black paint – so named because of the steam used in the manufacturing process. His team based their design off the helmets worn by soldiers in World War I.

Soon the construction industry began to adopt this type of protective headgear, along with other industries liking the mining industry. And by the 1930s, fiberglass was introduced as a stronger and more durable material, replacing the earlier canvas designs.

In the 1960s, the American National Standards Institute (ANSI) established safety standards and introduced color coding to differentiate roles and responsibilities of hard hat wearers. Since then, advances in materials like high-density polyethylene have further improved hard hat durability, and many modern hard hats have built-in ventilation and adjustable elements for comfort.

the future of ppe

Innovative products like anti-vibration gloves and wearable gas detectors are quickly gaining traction in the construction sector, but according to the numbers, construction-related injuries aren’t exactly decreasing. Inventors and industry professionals alike will have to continue brainstorming new safety measures if we are to keep our construction workers safe. And, from smart helmets complete with augmented reality displays to the incorporation of biometric sensors, the future of PPE will undoubtedly build upon the ongoing advances in technology.